About Premier Aluminum Llc

About Premier Aluminum Llc

Blog Article

The 5-Minute Rule for Premier Aluminum Llc

Table of ContentsGetting The Premier Aluminum Llc To WorkLittle Known Facts About Premier Aluminum Llc.6 Simple Techniques For Premier Aluminum LlcOur Premier Aluminum Llc Ideas

(https://www.cybo.com/US-biz/premier-aluminum-llc_30)Traditionally, a buyer's primary duty was to discover certified and responsive suppliers. In many cases, buyers presumed that any type of supplier going to contractually meet the purchase demand was qualified. Utilizing reduced cost and unqualified suppliers can trigger quality concerns, and threw away time and money in the lengthy run. To assist you through the process, right here are some things to consider when selecting the ideal metal spreading distributor.

A firm that only utilizes the financial investment casting process will attempt to offer you on why that procedure is best for your application (Foundry near me). Yet what happens if utilizing the sand casting procedure is best for you and your requirements? Rather, search for a distributor that provides a variety of casting procedures so the very best alternative for YOU is picked

If working with a single resource for all of your spreading requires is necessary to you, the provider needs to be diverse in its capacities. When integrated with various other integrated capabilities, this can aid simplify and press the supply base. When picking the appropriate casting supplier, mindful factor to consider should be offered to high quality, solution, and price.

The Greatest Guide To Premier Aluminum Llc

Purchasers significantly choose casting vendors who have machining abilities. This can prevent problem if defects are found throughout machining. If a 3rd party is machining, it may lead to "finger-pointing" about that is at fault. Is it a spreading concern or a machining concern? If the spreading provider finds a problem throughout machining, the problem is solved much faster without any disagreement over whose fault it is.

What do you require from your spreading distributor? Are you looking for somebody to simply provide a metal component to your doorstep or do you need more?

Others will surpass the letter of the PO to assist you conserve time and money. Do you have needs for both ferrous and non-ferrous alloys? Some foundries are minimal or specialized. Make certain the vendor can meet all your product or alloy requirements to get rid of the demand for several suppliers.

Unknown Facts About Premier Aluminum Llc

Research the vendor's web site. Talk with a sales rep or company partner. Ask a lot of questions. Visit their center. Obtain an understanding of what they can do for you and if you can see on your own developing a solid, shared relationship with them.

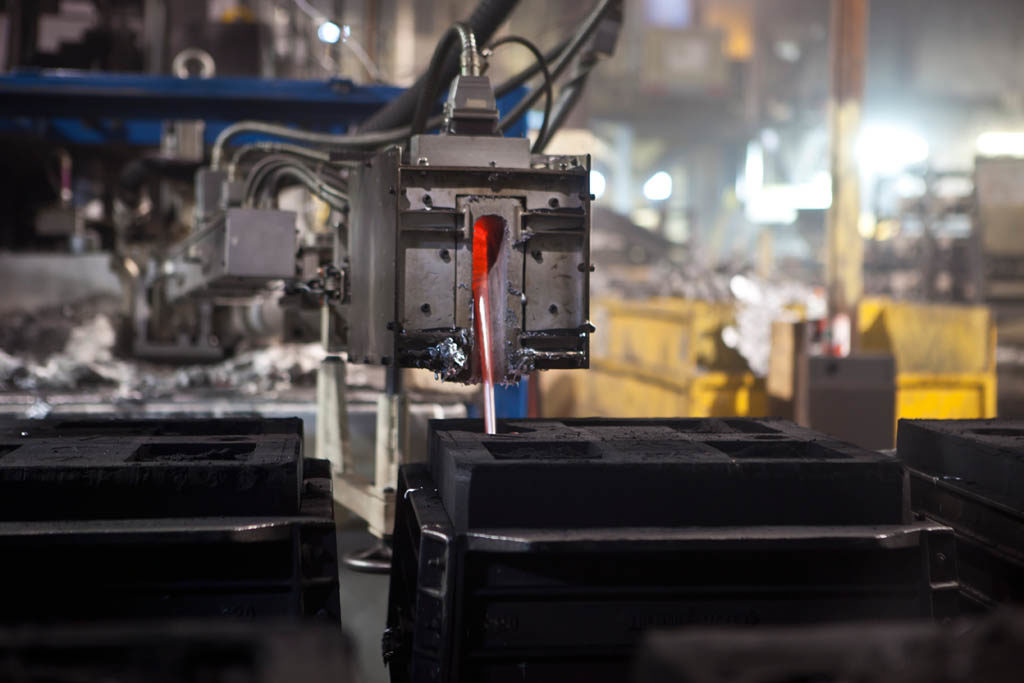

Light weight aluminum is also over at this website lightweight and has great corrosion resistance, making it suitable for applications where weight and sturdiness are vital aspects. In addition, light weight aluminum spreading is a cost-efficient method of production, as it requires much less power and resources than other techniques. Iron spreading, on the various other hand, involves putting liquified iron right into a mold to produce a desired shape.

Premier Aluminum Llc for Dummies

Iron spreading is likewise able to stand up to high temperature levels, making it appropriate for usage in applications such as engine parts and commercial equipment. Nonetheless, iron spreading can be a lot more pricey than light weight aluminum casting due to the higher price of raw products and the power needed to thaw the iron. When choosing between light weight aluminum spreading and iron casting, it is essential to think about the particular needs of the application.

In final thought, both aluminum casting and iron casting have their very own special benefits and downsides. There are three sub-processes that fall under the classification of die spreading: gravity die casting (or permanent mold casting), low-pressure die casting and high-pressure die casting. To obtain to the ended up item, there are three primary alloys used as die spreading product to choose from: zinc, light weight aluminum and magnesium. Report this page